CNC WORKHOLDING SOLUTIONS FOR EFFICIENT MACHINING

PRICE. DELIVERY. QUALITY.

About Us

Request a Quote

Services

CARBIDE TOOL MANUFACTURERS

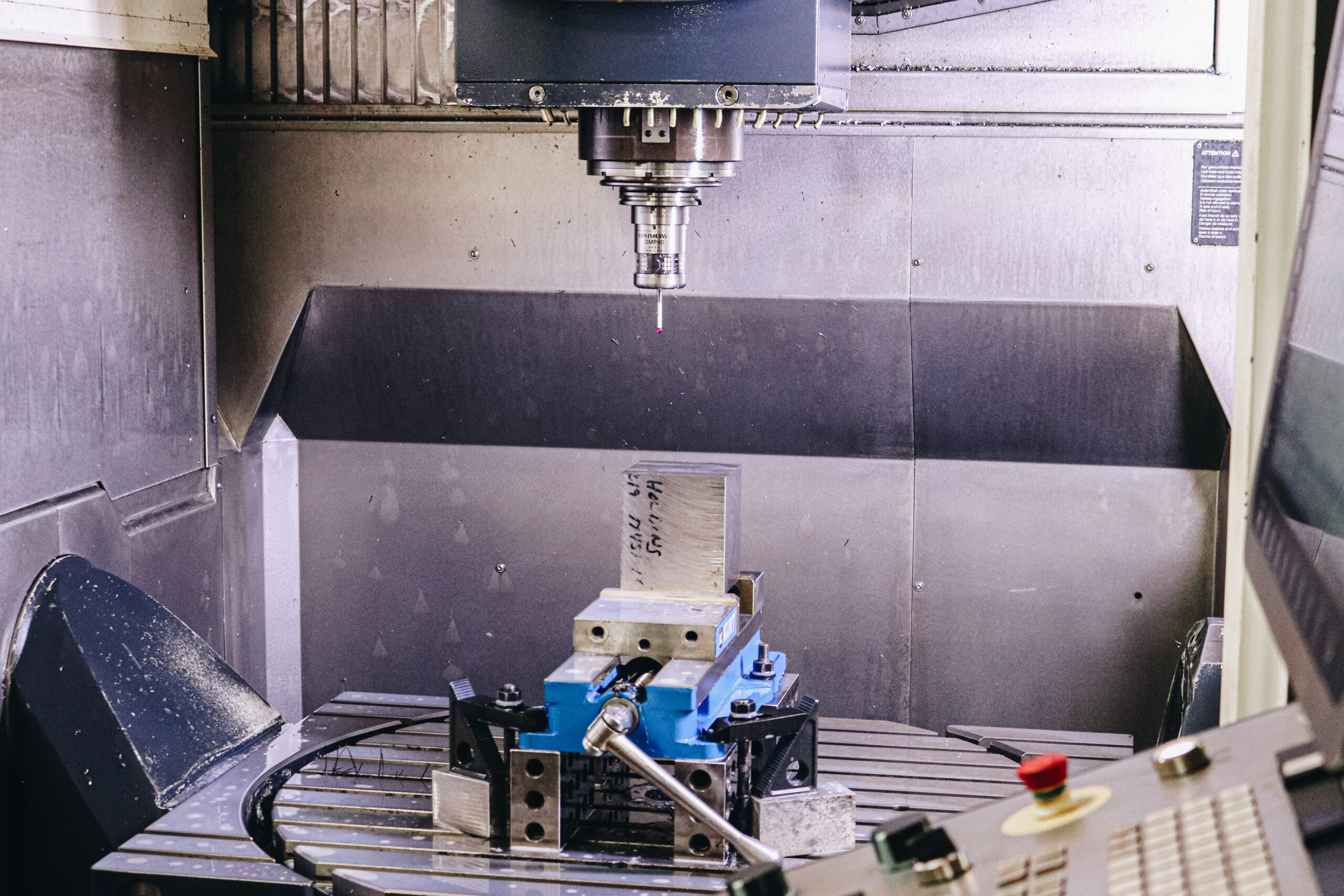

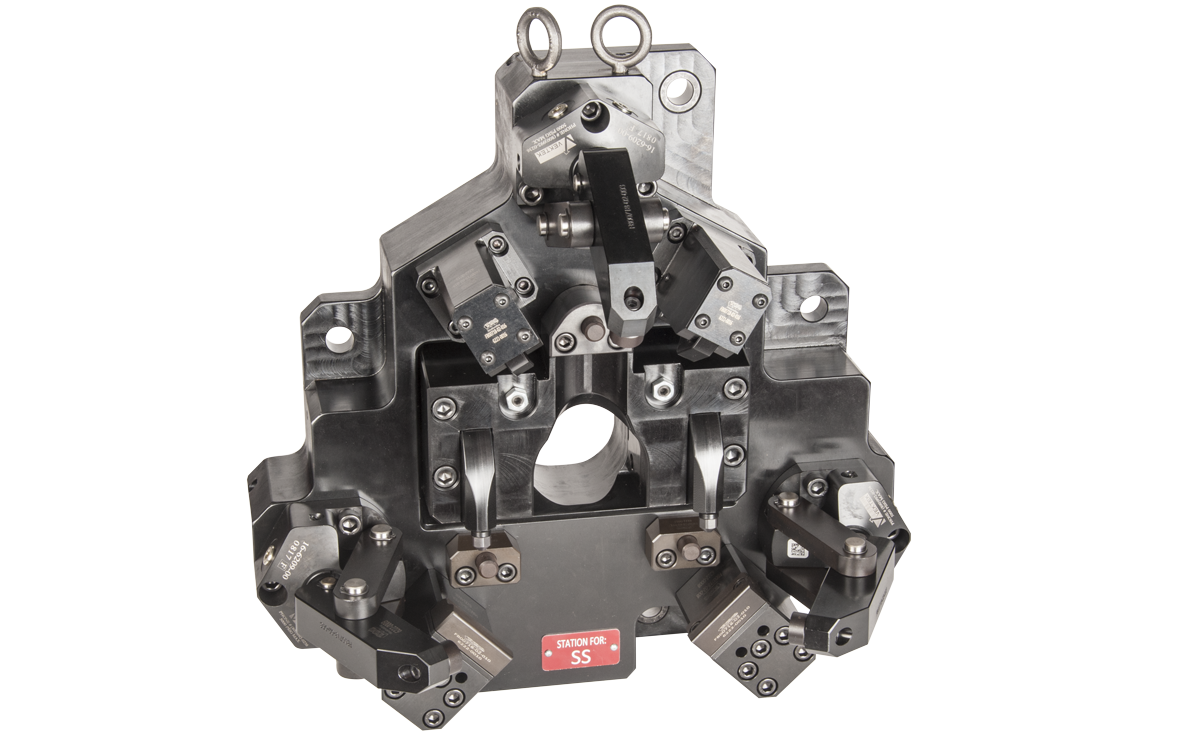

PDQ Workholding is a modern tool shop focusing on the design and manufacture of part holding devices. Our core specialty is hydraulically-actuated machining center fixtures. . The PDQ strategy is to employ the brightest personnel using the newest technologies to provide the lowest Price and quickest Delivery, while maintaining the highest level of Quality.

Our goal at PDQ is to provide our customers with the best possible workholding solution to make their project go as smoothly as possible. We stand behind our work and will support our customers if issues arise at any phase of the project. Lean operating practices and short chain of command allow us to react quickly and effectively. Workmanship on all fixture components is also backed by a two-year warranty.

PDQ Workholding is a modern tool shop focusing on the design and manufacture of part holding devices. Our core specialty is hydraulically-actuated machining center fixtures. The PDQ strategy is to employ the brightest personnel using the newest technologies to provide the lowest Price and quickest Delivery, while maintaining the highest level of Quality.

Our goal at PDQ is to provide our customers with the best possible workholding solution to make their project go as smoothly as possible. We stand behind our work and will support our customers if issues arise at any phase of the project. Lean operating practices and short chain of command allow us to react quickly and effectively. Workmanship on all fixture components is also backed by a two-year warranty.

FAQ’s

How does PDQWH specialize in CNC workholding solutions?

Our sales and engineering team work closely with the customer to develop the best strategy for their high production machining needs.

Can PDQWH provide custom workholding solutions for my specific needs?

Yes, it is our specialty to solve all of your custom workholding and tooling needs.

How does PDQWH approach workholding fixture design?

We approach each project with the goal of providing a sound solution that maximizes output with the highest quality utilizing ergonomics for human or robotic use.

Are custom workholding fixtures different from standard ones?

Yes. Custom workholding is designed for the specific needs of an individual part (or family of parts) to be fixtured for a high production environment. Standard fixtures are sometimes not the best solution to locate and hold a part adequately for its machining and production requirements.

What advantages does PDQWH offer with its hydraulic fixture builder?

Hydraulic fixturing gives you the best solution for stability and location of the part along with repeatability in a high production machining scenario.

Does PDQWH collaborate with carbide tool manufacturers?

Yes, as well as many other tool manufacturers.

What materials are typically used in PDQWH’s workholding fixtures?

Our fixtures are built mainly from steel. We do offer cast iron, aluminum, and stainless steel as required for specialty workholding solutions. We also utilize non-ferrous materials for part touching were needed.

How can I ensure my CNC machine is compatible with PDQWH’s workholding solutions?

No Worries! Our sales and engineering team will do that for you!

We will discuss your equipment along with how to incorporate a workholding solution to meet your needs.

What industries typically benefit from custom workholding fixtures?

Automotive, heavy equipment, agriculture, oil & gas, aerospace, mining, medical, nuclear.

How does hydraulic workholding differ from other types?

Hydraulic clamping utilizes high pressure fluid in a closed circuit to precisely control the action of the clamping and locator devices on the fixture. Manual clamping is uses manpower to tighten, loosen and locate the part(s). Other means such as light activated, vacuum, or cryogenic clamping offer solutions particular to certain parts but with lower production.

Why choose PDQWH for custom workholding solutions over other providers?

We are committed to providing our customers with products and service that meets or exceeds their expectations! We partner with our customers to develop workholding and tooling solutions to support their manufacturing needs.

What is the role of carbide tool manufacturers in PDQWH’s offerings?

Just like our one off special custom fixturing & indexable tooling we can offer the same for solid carbide tools. We have the abiliity to design & mfg application specific drills, end mills, reamers, form cutting tools, and anything else that can be made from carbide rod.

How does PDQWH maintain quality and precision in their workholding products?

All fixtures are checked on our Zeiss cmm with adjustable shims for all locating features. This gives us the ability to dial in all critical locating features and eliminate any tolerance stack up issues.

Can I request a custom design for a workholding fixture based on my machine’s specifications?

Yes, it’s our specialty! We are happy to discuss your needs for any workholding solution.